Temporary Works: Temporary Structures

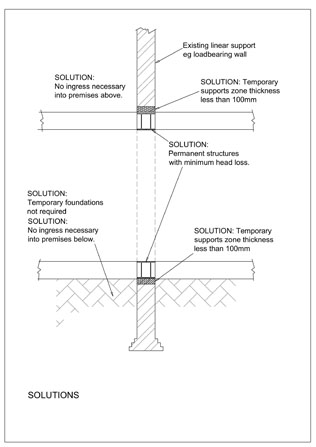

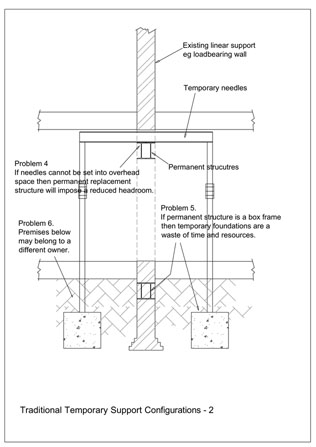

Solutions...

C-Prop™ addresses and resolves all of the above problems and reduces the costs by eliminating the abortive works and by minimizing repair works.

C-Prop™ can sometimes be inserted into the subject structure from one side only, therefore blocking access only to one side of the wall. This could provide that the other side of the wall is unobstructed by temporary structures therefore offering a flexible and free work space for the purpose of installation of permanent supports.

C-Prop™ can be reduced in thickness at the top and bottom supporting locations, where it is inserted into the supported wall thus allows for construction of permanent beams with minimum loss of headroom. Typical thickness in the region of 40-50mm can be achievable, which should be adequate for most applications. This could be reduced even further if necessary.

See first diagram to the right.

Solutions...

When C-Prop™ is installed in its designated location, its proprietary system enables it to be tightened and loaded into the existing structures. This ensures that the wall above the temporary supports will not settle by any material amount.

Wherever gaps may open between any component sections of the C-Prop™ during assembly and loading, solid blocks are introduced as necessary to ensure full strength physical contact of all elements on the temporary loadpath.

Solutions...

C-Prop™ completely cancels out any requirement for installation of temporary foundations structures through its advanced geometry and precise and controlled compensation of design loadings.

C-Prop™ units are typically manufactured in grade S275 steel with FPBWs at all connections of fabricated sections. All connections are executed with grade 8.8 bolts, fully tightened and secured using TW’s own enhanced security system.